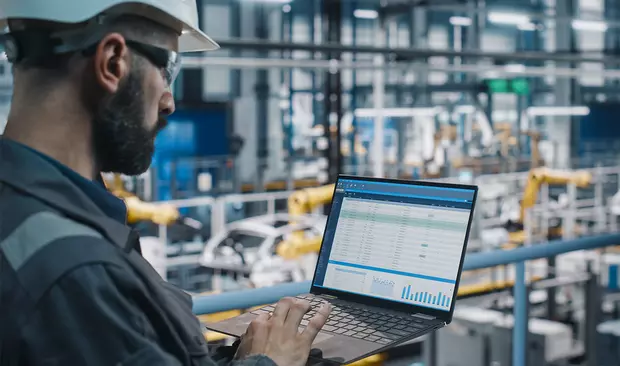

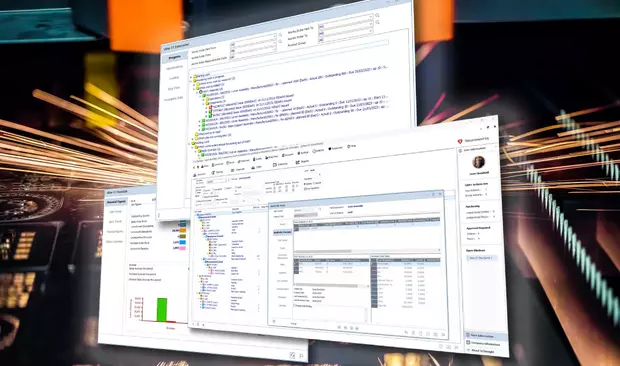

The power of portability: Extending ERP's reach for growth

Implementing an ERP system is essential for companies aiming to achieve sustainable growth. However, if you're not including portable devices or handheld technology into that mix, you may be missing a trick.