MRP Software Implemented At Ovation Systems Ltd

After using 123insight MRP Software since 2007 a consultant recommended that the company select an ERP system instead, to cover more of their business. After a year and a cost of over £100k, Ovation came back to 123insight and have since seen reaped the benefits of switching back.

Selected as best MRP system

- Selected and re-selected as the best solution

- Replaced system costing around £100,000

- 20% faster to use than previous system

- Massive paper reduction

- Sage interface

- Linking to Omnify (PDM) for BOM control

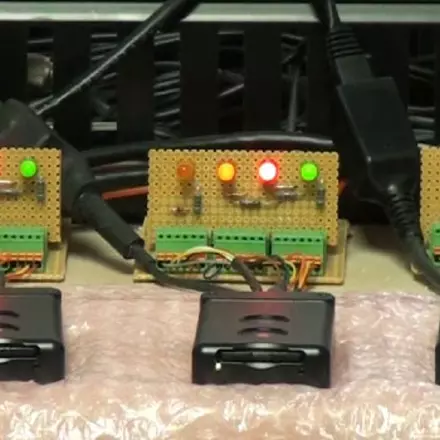

Ovation Systems Ltd, based in Milton Common, Oxfordshire, design and manufacture high quality covert video surveillance equipment. In 2007 the company was relying on a paper-based system linked into a standalone database. Andy Wagerfield, Production & Quality Manager explained; “The only electronic system we had at the time was a sales database, which started out as a stock control system. The decision to select 123insight was made quite quickly and the task of implementing it was passed to me.”

Initial selection and implementation

Andy attended the user training courses and a colleague attended the administration and implementation courses in March 2007. Andy found the training provided him with a solid basis to move forward with installation; “It gave everyone a good grounding in what they need to do. The trainers are very good, know their stuff and are very helpful.”

The company went live in June 2007 and continued using 123insight until 2012. They were considering implementing ISO9001:2008 and an external consultant advised them that they required a single ERP product rather than separate systems. Andy noted; “I was always quite happy with 123insight, but they wanted more of an all encompassing system, which is why we looked at other ERP systems. It was perceived as ‘going to the next level’. The financial case did not come into it - it was more the selection process of getting the right system.” Jeremy Rowe, Director of Operations, added; “Before I joined we were moving towards ISO9001:2008 and received advice from a consultant that there were a number of ERP systems around that we should consider moving to. We were advised to get a single system that not only handled finance, manufacturing and purchasing, but also integrated the issue tracking that is necessary to demonstrate that you are taking corrective and preventative action and all those other things related to ISO accreditation.”

Replacing 123insight with a different ERP

A system costing around £100,000 was selected and Andy set about migrating data and learning the new system, but immediately hit problems; “One of the things I was very strict about was that I could do exactly the same in the new system as I could in 123insight - I was very specific. I showed them how we collected online test results and was assured that the new system could do that. It was not quite true and we were mis-sold from the beginning. There was an awful amount of training we had to go through to just get to a stage where we could use it.”

Despite replacing 123insight and their accounts system for a single ERP system Ovation continued to experience problems. Andy explained; “The final nail in the coffin was when we did the stock take at the beginning of 2013 - it all went wrong as there was a large amount of stock that was duplicated and put back into the system. Also, serial numbers were duplicated, so we had certain areas of stock that were doubled and had duplicate serial numbers, so it was proven that the system could break its own rules.” Jeremy added; “Leading up to that we'd had all sorts of issues with the system. The user interface was particularly hard, especially if you are not using the system all of the time. The amount of time that we spent trying to do things was not proportional to the information we got out of it. Instead of helping us it was an impediment to us doing business. We took a decision that we could no longer continue with the other system. 123insight was a known quantity - we knew what it could do.”

Reverting back to 123insight

The decision was made early in 2013 to revert to 123insight and Sage accounts, with data exchange between the two handled automatically by AAI (Advanced Accounts Interface). Jeremy noted that the previous integrated accounts solution had not delivered what it promised; “Accounts were previously a nightmare. We could never get a sensible set of management accounts out of the old system.”

Since the implementation of 123insight we are very clear about our stock position... ...it’s about 20% faster for me to do what I want to do in 123insight than previously.

Migrating data from ERP to ERP

Data migration took place between March and May, although overall stock valuation was a problem as Jeremy explained; “When we did our first transition from 123insight into the other system the standard cost of each product rather than actual cost was used by the new system. All of the batch costs should have come through so that we would have a complete portfolio of all of the batches and varying costs but again it was the standard cost that was used. More than that, there were some holes in the data. When the time came to do our accounts and stock valuation for the end of 2012 it was very hard to reconcile what we had in stock versus what we knew we had during 123insight's first time - and these were not small amounts, they were hundreds of thousands of pounds. You can't tolerate that kind of uncertainty. Now since the re-implementation of 123insight we are very clear about our stock position.”

Integrating ERP with other systems

There were a number of new features that Ovation were able to take advantage of the second time around. The SDK allowed them to pass data between 123insight and other systems, and the software also allowed them to build up a service history of items during their lifetime.

Andy attended refresher training courses, and Jeremy attended his first training courses. He noted; “My first experience of training was two separate courses, and I found it very helpful. I can do most things that I need to do without looking it up, but I probably only use the system 2-3 times a week. It's not difficult for me to find my way around.”

Go-live and immediate benefits

After going live day to day operations became much simpler. Said Andy; “It was just a relief really. The biggest issue was getting the test procedures in so that we could perform the online testing for products. It was so seamless once we'd moved back to 123insight, as most of the staff were already used to using it. Once the data was in it was very simple.” Jeremy also found benefits; “I personally find that it takes me around 20% less time to do things in 123insight than previously.”

As with many electronics companies, Ovation offers its customers options to service or repair items. The previous system handled this through it’s ‘RMA’ functionality, but 123insight provided a much more robust solution; “It's very good at tracking repairs through, giving a permanent history of the life cycle of a product once it's been sold.”

Logging of test data

Each product undergoes ‘online testing’, and this information is now fed automatically into 123insight, with the records logged and accessible by all staff. Paperwork reduced drastically through the business, as test results previously were printed and stored, with Andy citing that ‘four racks’ of paper were being used to store previous records, and they no longer needed to allocate storage space for future records.

The company are also using Omnify Product Data Management for advanced BOM control, and are currently implementing a direct link, developed by 123insight partner Solweb using the 123insight SDK. Omnify holds the master BOM data, which includes more technical product information, revision control and links to related documentation. All relevant information will be automatically synchronised with 123insight via the SDK, safe in the knowledge that any future updates to either product will not break the communication link.

With ISO accreditation and two Queens Awards for Industry already under their belt, Ovation’s focus on product quality and innovation is clear. After experiencing that the ‘jack of all trades, master of none’ expression rings painfully true they selected the best in class product for each specific task in their organisation. Jeremy finalised; “This business could not run unless we had a system like 123insight. We've augmented that with these other systems which are all really good in their own way.”

Find out more

If your company is experiencing similar problems to this case study customer, why not talk to us about how 123insight could be a good fit for your business. There's no commissioned sales people, so no hard sell - just an educational approach to helping you understand what MRP should be doing for your business.

Complete this form to find out more.