MRP For Industrial Physics Product Integrity

The company's previous DOS-based MRP system vendor had been acquired by another company, and they saw pressure from the vendor to move to a much larger system at great expense. After selecting 123insight for their new MRP software, they saw a massive reduction in paper. They are also working with 123insight to develop the Service Repair Centre product.

An integrated MRP system

- Massive reduction in paper

- Integrated ERP, Accounts and CRM

- Expands further into the business than before

- Are able to run 123insight over CITRIX for their US organisation

- Low monthly subscription

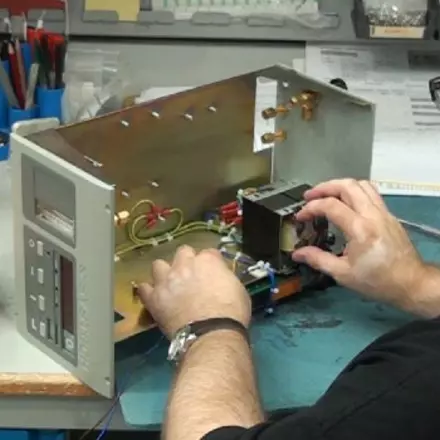

Industrial Physics Product Integrity Ltd (formerly Systech Instruments Ltd), based in Thame, Oxon manufactures industrial gas analysis equipment. Their previous MRP system was predominantly DOS-based with a Windows front-end, was very slow in operation and was not user-friendly. Steve Hanks, Company Secretary commented; “It had an estimating package which was more of an add-on than an integrated module, but it was so slow our sales staff refused to use it. The business ran around the MRP rather than the MRP fitting the business. After the MRP vendor was acquired by a larger company it was fairly apparent that they had no interest in developing the product further. I got the impression they were leading us down the line of a much larger system than we actually required. We would have to spend a sum with a lot of zeros and a number at the front, and we weren’t sure what that number would be. This led us to a point where we needed to investigate what alternatives were available.”

The evaluation process

The company heard about a 123insight Evaluation Workshop running at University of Hertfordshire, and the MD, Sales Manager and Production Manager attended. They provided Steve with the 123insight multimedia DVD which he ran through. After reviewing the contents and internal discussions the company made the decision to move forward in October 2006, which Steve cites as unusually fast; “The Evaluation Workshop approach was obviously quicker. In the conventional sales process one is used to a salesman living in your boardroom for as long as is necessary to sell you the product. The Workshop made it much easier than the usual tortured selling process.”

Two staff attended the training the same month on the understanding that if they then decided not to move forward with 123insight they could walk away without any costs.

Industrial Physics then spent several months cleansing their data and formatting into Excel spreadsheets for importing into 123insight. Steve cited that although it was a time consuming process, with many spreadsheets having 20,000 records, it provided a benefit of starting on a new system with clean data.

The go-live process

The company went live at the beginning of April 2007. Steve recalls; “The week before we went live we provided downstream training to all staff and did the final transfer of data over. We went live on the Monday in a big bang concept across the whole company. From a standing start we were up and running and operational immediately, getting payback from day one.”

The sales department was the first to see major benefits. Previously estimates were raised outside of the MRP system, but now they were creating quotes and adding prospective customers within 123insight. These were then available for immediate conversion to orders, providing a considerable time saving.

Essentially it was operational immediately and we were getting payback from day one... There are always significant features in each new release and this provides long term benefit to our business.

Manufacturing visibility

Visibility of stock and work in progress also improved; “The whole process was much more streamlined and operationally staff found it much easier to use the system for day to day tasks such as allocating time to jobs. You now have a window on stock as and when you want it. We now have fewer stock issues and errors because of the ease of use of 123insight.”

Paperwork saw the biggest reduction; “We took a decision during implementation to attempt to significantly reduce the amount of paper we throw around the building. The ability to store and email documents electronically means that we don’t need to keep hard copies in filing cabinets. As a result we have literally saved a small forest! We now just have one printer/copier where in the past we would have three or four.”

Linking to testing

123insight is also now being used in areas that Steve had previously not considered. He noted; “Our test area, which previously would never have been anywhere near our MRP system is now used for inputting repair costs. We now use 123insight in many more areas of the business than we could with the previous system. The advantage is that you are only paying for an extra license rather than another module, which would have been the only option with other systems. It’s cheaper and relatively painless as well.”

Steve was extremely pleased with the relationship he formed with 123 Insight Ltd; “The staff are well trained and know the product. We always feel that we are being helped and supported, especially in the areas that we do not have expertise in.”

Integrated with accounts

In July 2010 they implemented Access Dimensions accounts, which benefits from tight integration into 123insight due to the two systems sharing SQL database structures. Users can now view live accounting information directly from within relevant 123insight screens, such as customer or supplier records.

The company has just gone live with 123insight’s CRM module, and their sister company in the US will soon also migrate to 123insight, running over a CITRIX network. Steve finalised; “123insight provided us with a low cost of entry. It certainly brought everything we thought to the party, but we did not expect the benefits of the continued development and that they are always striving to move the product forward. It is a big comfort.”

Find out more

If your company is experiencing similar problems to this case study customer, why not talk to us about how 123insight could be a good fit for your business. There's no commissioned sales people, so no hard sell - just an educational approach to helping you understand what MRP should be doing for your business.

Complete this form to find out more.