MRP System For C & J Marine Ltd

C & J Marine previously relied on an in-house built Access database and separate spreadsheets. After discounting systems costing £50k+ and annual running costs of £10k they selected 123insight's MRP system. Lead times have improved by 5%, as have errors, and the company can now perform location-based marketing campaigns.

Improved stock control with MRP system

- Lead times improved by approx 5%

- Errors reduced by approx 10%.

- Stock down by 5%

- Consignment stock handling

- CRM and SFDC made significant impact

- Equipment Register allows for targeted location-based marketing

- Low monthly subscription

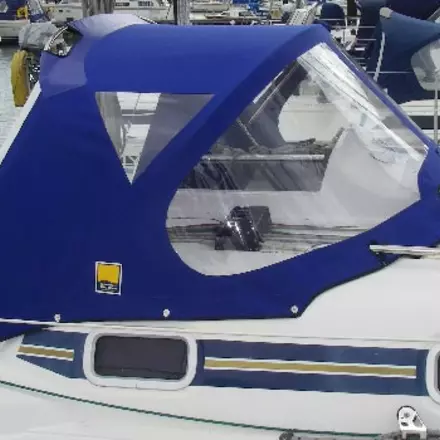

C & J Marine Ltd, based in Chichester, West Sussex, manufacture canopies, covers and upholstery for the marine, garden and leisure markets. They previously relied on an in-house developed Access database, along with separate Excel spreadsheets which became less suitable as the company expanded. Wayne Strickland, Operations Manager explained; “Our Access database could not integrate with Sage and had other limitations - we could not record job runtimes or customer information, such as where boats were moored. Finding out how much a job actually cost us was very difficult. In some cases it was taking up to a year to get costing information back so that we could see if we made money on a job. As time went on, it was not supported that well and was becoming unstable. We identified that we needed a system that would better support the sales side of the business, which also led us into MRP and exploring full business system integration.”

MRP evaluation and selection

With that in mind C & J started to evaluate the market, looking for systems that would not only meet their manufacturing needs but that could also provide better communications with their sales department. They investigated systems costing up to £50,000, with annual costs of around £10,000. Wayne noted; “They just seemed to be massive, yet didn’t actually cover some of the points that we were trying to address. They had lovely gant charts and it all looked very nice, but when we drilled down they were not going to help in some of the areas of the business that we wanted to improve, such as recording labour times. You could not actually record the time spent on the shop floor and view that data quickly. Of course, there was also the cost - a phenomenal amount! We did not have that amount of money to spend up front and it would have taken years to see a payback, so it was simply a no-no.”

C & J were recommended to attend a 123insight Evaluation Workshop, which they did in Summer 2008. Wayne found the approach a refreshing contrast; “It was almost like a simple step process. The 123insight staff were very professional, and explained it very simply – it just seemed to make sense.”

Accounts and data migration

The company registered to receive the software in October 2008, and then started to assess how they would migrate from their Access database in February 2009. At this point they realised that they would have to re-evaluate their entire business processes; “Getting the server ready and installing 123insight only took a couple of days. Then we realised that we had to take a fresh look at the business. We had 20 years of data to migrate, covering customers, parts, BOMs etc, but this gave us the opportunity to spring clean the data. We devised a coding system so that we could instantly recognise certain criteria from the part number alone - what the part was, which boat brand it was for and its colour. This approach has been used right across the company - every photo or drawing is coded with that reference, providing full traceability across the board.”

Reshaping their data and changing their work processes took over a year, with the company going live later than planned. Wayne noted; “It was a relief to go live. We went from opening various pieces of software to just one place to retrieve information. We had customer information, boat locations and part information all integrated and in one place rather than split across databases and spreadsheets.”

Collecting data on the shop floor

Shop Floor Data Capture (SFDC) provided instant benefits. C&J could immediately see if a product was stalling during production. They could also instantly report on how much a job had cost to manufacture. Lead times also saw an improvement of 5%, with Wayne citing better communication between sales and production via 123insight’s CRM option as playing a significant role; “We are being much more efficient in the way that we do business with our customers. With the CRM/MRP link our production team can advise sales if there is a window of availability within production in the future so that they have the opportunity to fill it.”

CRM has benefited the company across the board, allowing the sales team to be more proactive in following up leads and also being used as a support mechanism for customers. Wayne explained; “It’s changed the way that we support customers. Previously we had customer and boat details in a separate database but had no way to record notes or conversations, or to associate drawings or emails. Everything was paper-based, with hand-written notes on the back of sales orders. With CRM we now have a process in place where all customer conversations, no matter how small, are recorded.”

If you compare 123insight with the traditional way of selecting an ERP/MRP system then you’ll get a much quicker ROI than spending tens of thousands up front followed by thousands per year for ongoing support. You just need to do the maths.

Improved stock control

Stock amounts also reduced by around 5% as C&J have better forecasting over future requirements. As there is now a direct interface between 123insight and their Sage accounting software through AAI (Advanced Accounts Interface) errors, most caused during duplicate data entry in the past, have also seen a significant reduction of around 10%.

Much of C&J’s stock is supplied on a consignment basis e.g. they pay for it only when it is used. 123insight allows them to create a consignment stock location that is excluded from stock valuation reports, therefore providing a true stock value. As stock is moved from the consignment location to another location it will automatically appear on stock reports.

Equipment register

C&J selected 123insight partly because of its Equipment Register facility. Their previous database allowed them to store a boat’s location and marina berth number against a customer record, but did not allow them to easily categorise or mine the data. In addition to the full logging of customer communications and documents, 123insight also allows them to group customers into geographic zones, which Wayne now uses for targeted marketing campaigns; “It was fundamental to us to have this information stored in a single location that could be used by all elements of the system. When we attend local shows we can now easily send an email to all customers that keep their boats in a given area, for example on the South Coast.”

C&J meet the 123insight customer average of one support call per month, with Wayne happy with the service they have received; “We’ve always found the 123insight staff quick and professional as and when we’ve needed support. They are knowledgeable and also resolve any issues quickly. It’s nice to know that the safety net is there if we need it.”

Integrated e-commerce using SDK

The current www.cjmarine.co.uk website is due to be replaced with a new e-commerce system that will interface directly with 123insight using the available Software Development Kit (SDK). This option allows customers to develop powerful and stable data transfer between 123insight and third party applications, safe in the knowledge that updates to any system relying on the SDK will not corrupt the 123insight SQL database. When Wayne was discussing website integration with possible ERP/MRP vendors he was greeted with a mixed response; “In some cases they said ‘You can’t link a website directly to your database - there needs to be a database or software to take the information from one system to another’, but with 123insight we can now involve a 3rd party web developer that can take information in and out of the system directly.”

The company is currently developing new ranges for different market areas as well as standardising some products to fit a range of boats. Wayne sees 123insight as a core foundation of the business that pays for itself much quicker than any other system. He finalised; “If you compare 123insight with the traditional way of selecting an ERP/MRP system then you’ll get a much quicker ROI than spending tens of thousands up front followed by thousands per year for ongoing support. You just need to do the maths. If a company is looking to integrate all of their business systems then 123insight will do it. It will integrate all of your business processes, and that is fundamental in my opinion as to how any business needs to move forward in the future.”

Find out more

If your company is experiencing similar problems to this case study customer, why not talk to us about how 123insight could be a good fit for your business. There's no commissioned sales people, so no hard sell - just an educational approach to helping you understand what MRP should be doing for your business.

Complete this form to find out more.