ERP software and Quality

123insight provides complete control and visibility of your suppliers, their products and performance. Your quality team can monitor and track the quality of raw materials and finished goods, ensuring consistency across all products.

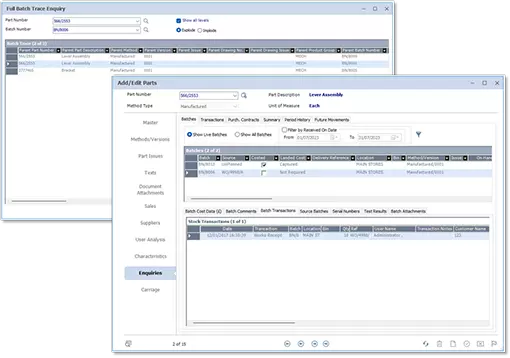

Furthermore, 123insight can help your company to obtain and retain quality accreditations by providing demonstrable traceability throughout the manufacturing process. It can track the complete history of a product, from its raw material to finished good, enabling you to easily provide auditors with compliance information, leading to a smoother accreditation process and makes it easier to retain them.

Batch Traceability

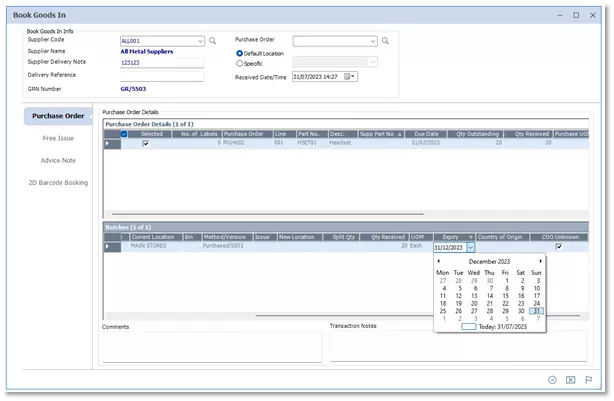

Batch number traceability is inherent and built into the fabric of 123insight. Whenever parts are received, unique batch numbers are generated, recorded and tracked through the system so you have full traceability from creation through to which of your products they were used in.

Goods-in Inspection

Manage quality inspection on a part by part and supplier by supplier basis using inspection templates and sample quantities set against individual parts. Even link 123insight to you inspection equipment using our SDK (link to SDK page) and record inspection results in the system.

Calibration

Manage your tools, jigs and machinery calibration in 123insight ensuring your parts and products are measured and setup correctly and your line never goes down because you discover an uncalibrated tool

Expiry Dates

Record and track expiry dates of parts such as resins, adhesives and paints from the second they are received into your business, ensuring you always have the visibility of material shelf lives.